Stepper Motors

Stepper Motors_FIVE STAR MOTOR

A stepper motor is a digital version of the electric motor. The rotor moves in discrete steps as commanded, rather than rotating continuously like a conventional motor. When stopped but energized, a stepper (short for stepper motor) holds its load steadly with a holding torque. Wide spread acceptance of the stepper motors within the last two decades was driven by the ascendancy of digital electronics. Modern solid state driver electronics was a key to its success. And, microprocessors readily interface to stepper motor driver circuits.

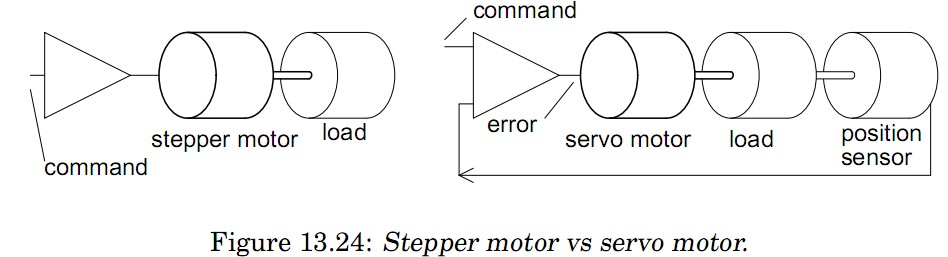

On the view of application, the predecessor of the stepper motor was the servo motor. Today this is a higher cost solution to high performance motion control applications. The expense and complexity of a servomotor is due to the additional system components: position sensor and error amplifer. (Figure 13.24) It is still the way to position heavy loads beyond the grasp of lower power steppers. High acceleration or unusually high accuracy still requires a servo motor. Otherwise, the default is the stepper due to low cost, simple drive electronics, good accuracy, good torque, moderate speed, and low cost.

A stepper motor positions the read-write heads in afoppy drive. They were once used for the same purpose in hard drives. However, the high speed and accuracy required of modern hard drive head positioning dictates the use of a linear servomotor (voice coil).The servo amplifer is a linear amplifer with some discrete componentsthat are diffcult to integrate. A considerable design effort is required to optimize the servo amplifer gain vs phase response to the mechanical components. The stepper motor drivers are less complex solid state switches, either on or off. Thus, a stepper motor controller is less complex and costly than a servo motor controller.

Tel:086-15938731655 Fax:086-0371-85228155

Tel:086-15938731655 Fax:086-0371-85228155